Bangalore, India – E7 Sewage Water Treatment Plant

Design, Supply, and Installation of Bolted Steel Sewage Treatment Tanks

Location: Bangalore, India

Duration: November 2024 – March 2025

The system was designed to handle the complete wastewater process — from aeration and anaerobic digestion to recycled and collection water storage.

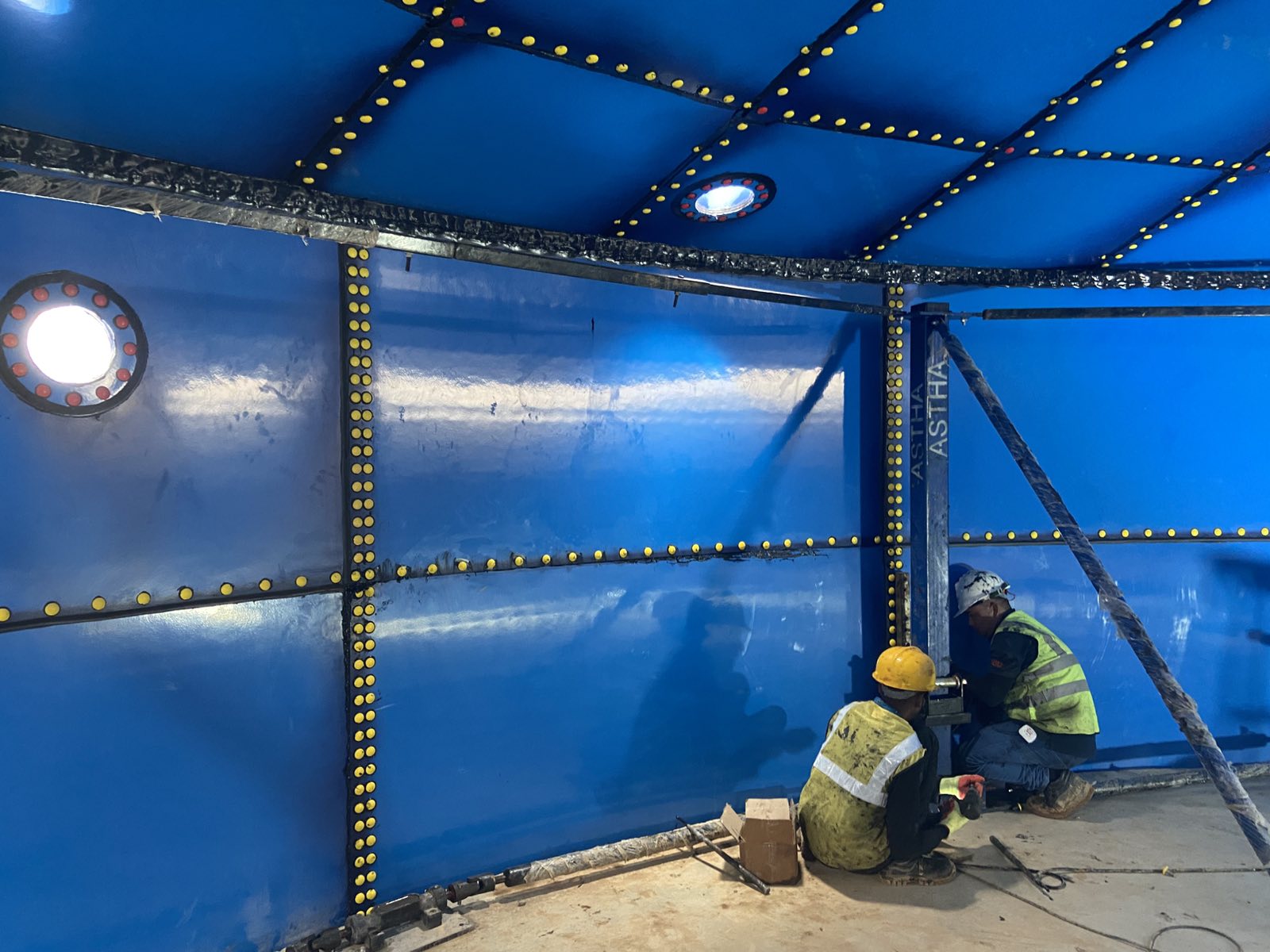

JAT Asia Pacific Tank Solutions completed the design, supply, and installation of twelve bolted steel tanks forming part of the E7 Sewage and Recycled Water Treatment Plant in Bangalore, India.

All tanks were prefabricated, dimensionally verified, and quality-checked before shipment, ensuring accurate bolt-hole alignment for rapid on-site assembly.

Installation was executed using a mechanical jacking system, enabling safe and efficient construction with minimal crane use.

Each tank was fitted with galvanized ladders, safety cages, and maintenance platforms for corrosion-resistant, long-term access.

All structures were designed and validated in accordance with AWWA D103-19 and Eurocode standards, covering wind, seismic, and hydrostatic design conditions.

Upon completion, the tanks were hydro-tested and fully QA/QC approved, confirming compliance with design parameters.

The project was delivered on schedule, providing a robust and efficient tank system that supports continuous sewage treatment and recycled water operations.

This installation showcases JAT's strength in multi-tank project management, prefabrication accuracy, and quality-driven field execution, aligned with international water infrastructure standards.